the arteries of your production

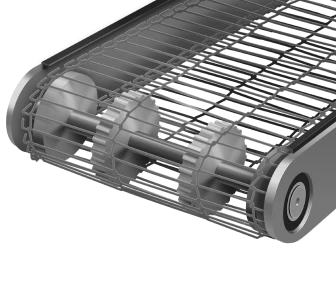

Direct conveyor is designed for horizontal movement of goods inside workshops and warehouses. It can be used as a separate conveying unit or assembled into a conveyor line. The length of the equipment, width of the conveying element, working height, speed of movement and load capacity are determined according to the customer’s specification.

The main purpose of the direct conveyor is to automate the process, minimizing manual labor. Horizontal conveyors are the most economical and easy to operate type of conveyor systems. Widely used in the production of various industries, as well as in warehouses, logistics complexes, sorting and assembly lines.

Direct conveyor is used to move products in the assembly and packaging areas, distribution of flows and transportation of goods between different areas of production.

We visit the enterprise, select a solution taking into account the customer's tasks, the characteristics of the transported product and the technological procss. We draw up a technical specification and prepare an estimate.

We are developing a technical solution, performing 3D modeling and engineering calculations. We are approving the project with the customer.

At the request of the client, we equip the conveyors with additional equipment and make adjustments. automated control of conveyor lines.

We carry out installation and commissioning, service, warranty and post-warranty service

We are training operators for subsequent pipeline maintenance