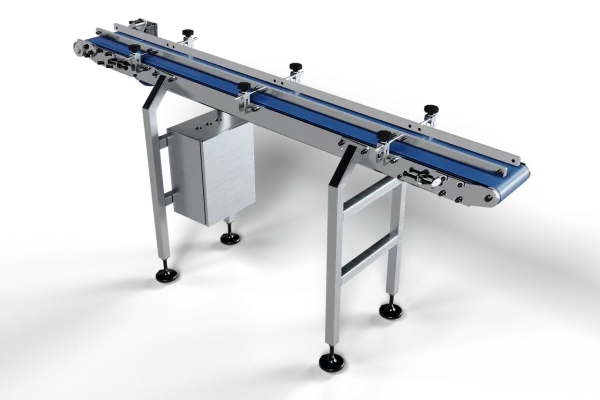

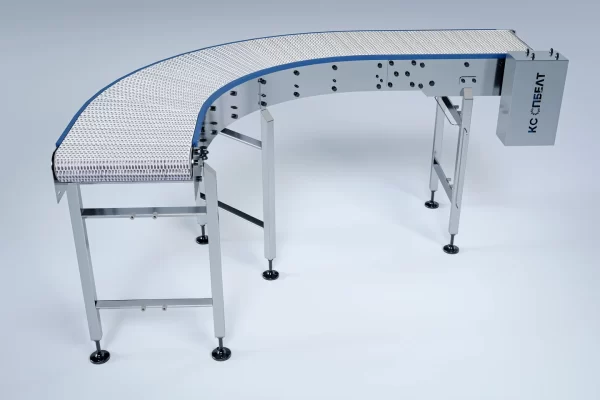

Mesh conveyor

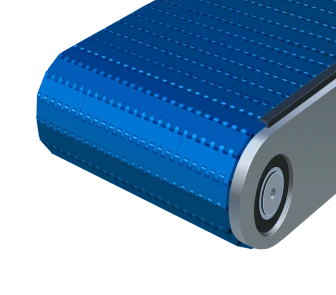

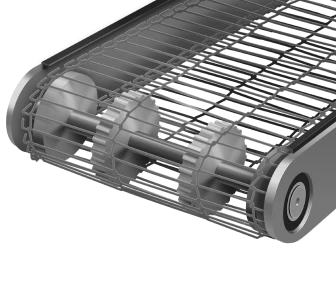

Mesh conveyor is a type of conveyors where a metal mesh is used as a transportation route. The principle of operation of conveyors based on metal mesh is similar to belt conveyors.

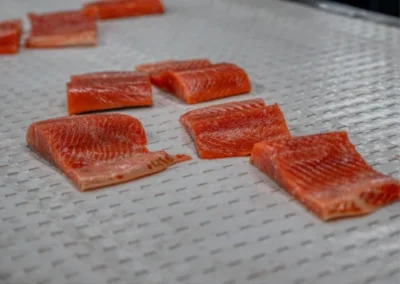

Conveyor systems based on metal mesh are used in the food industry, in the production of confectionery, meat and fish semi-finished products, bakery products, etc. Metal mesh works in a wide temperature range, provides water drainage, air circulation. This increases the efficiency of conveyors of this type in the areas of glazing, breading, sprinkling, in tunnel type ovens, in spiral systems in the process of cooling, freezing, drying, in washing plants, for screening and sorting products.

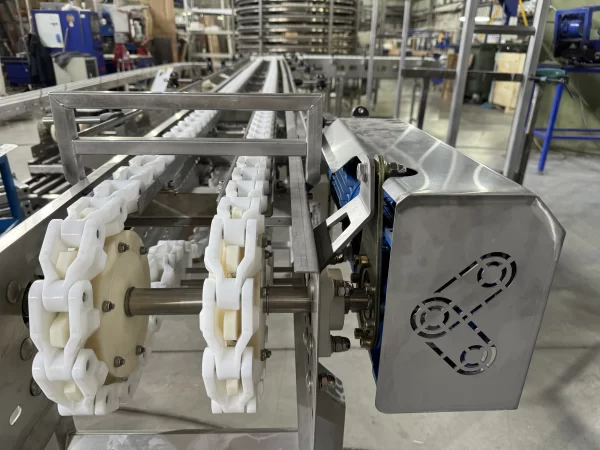

Mesh conveyors allow you to organize conveyor lines of different trajectory, based on the layout of the production shop: straight, curved, inclined, spiral. Depending on the process requirements it is possible to choose a stationary or mobile mesh conveyor.

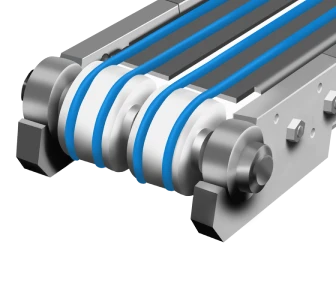

Based on the operating conditions and type of products mesh belts are made of carbon steel, corrosion-resistant steel, heat-resistant steel, nickel-chromium alloys, stainless steel with plastic modules.

Details