Task

The customer required a belt conveyor to transport mineral boards on a packaging line.

Solution

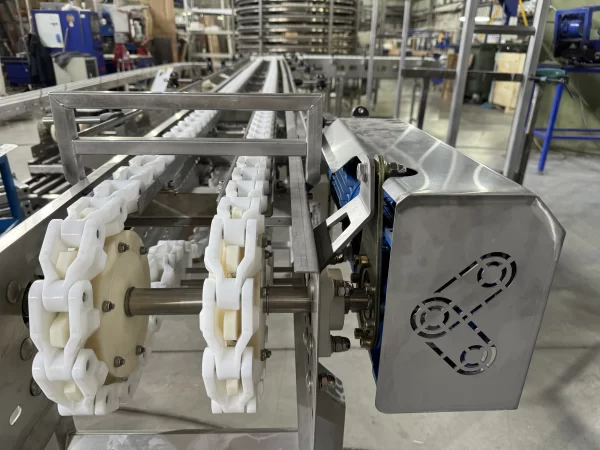

As part of the solution to the problem of efficient use of space in production, we designed and manufactured a curved belt conveyor. The angle of rotation in this conveyor is 90°, the maximum belt speed along the outer radius is 3 m/s.

The conveyor is equipped with a 1640 mm wide Chicago belt. The standard width for such belts is 400 -1200 mm. Belt movement is possible clockwise and counterclockwise.

A unique development of KS SPBelt company, applied in this project, is the belt fixation system. Our technical solution provides fast belt replacement without special tools, which significantly reduces downtime during conveyor maintenance. 2 skilled workers can replace the belt on the conveyor in 20-30 min. To replace the belt on a similar conveyor of other manufacturers will require 3-4 times more time.

Drive and driven shafts of conical shape have a special coating with coarse-grained structure to prevent slippage of the conveyor belt.

The conveyor can be used on supports or suspended.

Result

The SPBelt solution significantly reduces conveyor maintenance time, including quick belt replacement, thanks to the unique roller system locking system. The conveyor belt runs smoothly and quietly even at high speeds.

Curved conveyors have a wide range of possibilities for in-process transportation of packed and unpacked piece goods and are actively used in logistics and distribution centers, on packing lines and other spheres. KS SPBelt manufactures curved conveyors with rotation angle of 45°, 90°, 135° and 180° and weight load up to 150 kg.