Spiral freezers have become a real breakthrough in the food industry. They allow products to be cooled and frozen quickly and efficiently while maintaining their quality and freshness. Thanks to these processes, food can be stored for longer periods of time.

Spiral freezers are widely used in the production of seafood and fish, processed meat (dumplings, cutlets, meatballs, pancakes), mushrooms, berries, fruits, vegetables, as well as for cooling bakery and confectionery products, fermented milk products, etc.

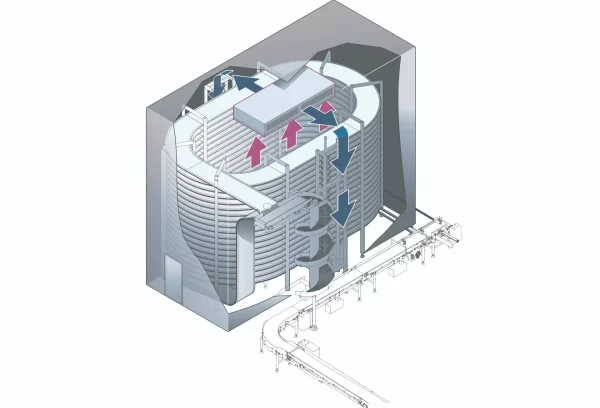

In contrast to the cooler, which can operate under conditions of natural cooling, for blast chilling in the spiral freezer additionally used thermal insulation chamber with a thickness of at least 120 mm, low-temperature refrigeration unit and a special industrial air cooler shockfroster.

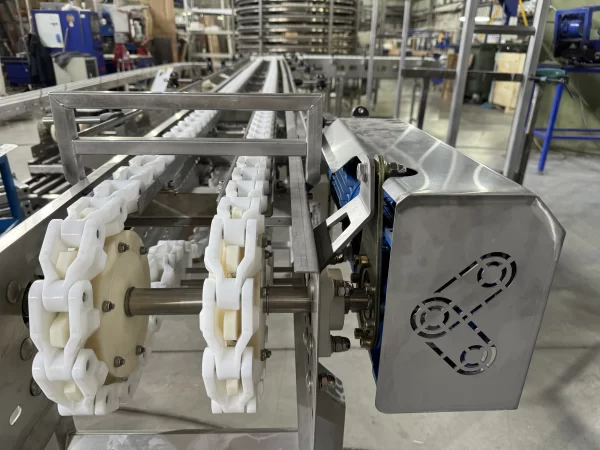

The spiral freezer can use a modular belt or a metal mesh as the load-carrying element.

Unlike other side-drive conveyors, the spiral freezer from KS SPBelt does not require lubricants in its operation because we used a stainless steel-polyethylene friction couple. The mesh moves on sliding profiles made of ultra-high molecular weight polyethylene, which ensures a constant low coefficient of friction between them.

The mechanism that drives the load-carrying element is the drive drum or the side drive. Their difference is that the drum is installed inside the spiral conveyor and is more expensive. A side-drive spiral freezer saves space by allowing it to be installed around structural elements, reduces costs due to the smaller steel structure, and makes it easier to maintain, wash and clean.

The choice between center drum and side drive, metal mesh and modular belts depends on the specific spiral conveyor requirements and operating conditions.

KS SPBelt designs and manufactures a spiral conveyor (spiral freezer) according to the technical task of the client, taking into account the specifics of the premises, the technological process and the transported product.