Task

A client working in the bakery industry approached us with an order to design and manufacture a bakery product cooling line. The order included 59 conveyors, including a cooler for the product cooling process.

Solution

As part of the project we developed a technical solution, performed 3D modeling and engineering calculations, made and implemented the installation of conveyor equipment, selected and installed refrigeration equipment.

Special attention should be paid to the cooler based on the spiral conveyor, on which the products with a certain speed descend from one production site to another. During the descent the bread cools down to the temperature required by the manufacturer.

The main advantage of this equipment is the side drive. The absence of an expensive central drum saves space inside the conveyor, i.e. if necessary it can be installed around the column or even place refrigeration equipment inside.

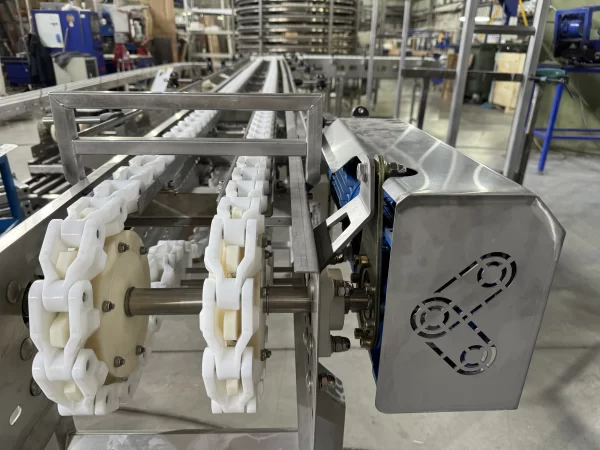

In the conveyor we have applied our own unique solution. Unlike other side-drive conveyors, it does not require the use of lubricants during its operation, because we used a friction pair stainless steel - polyethylene.

The split design of the drive sprockets ensures easy assembly and disassembly. The design of the sprockets with special tooth shape prevents the mesh from jumping between the teeth.

Also within the framework of the project 58 more units of equipment of various configurations were manufactured: flow unification/disconnection system (arrow conveyors), bridge conveyor, pusher, spiral chutes, etc.

All conveyors with modular belt used modular belt ML produced by SPBelt, High quality of components provides the Customer with stable operation of conveyor lines, and availability of a large number of spare modules and other components in our warehouses - prompt delivery of spare parts in case of need.

Result

A full-fledged technological line was installed at the production facility, the main stage of which was the process of cooling the bread.

We can design and manufacture a spiral conveyor of any capacity and configuration for freezing, cooling, proofing or product handling processes. Want to realize your project, write or call us.