the arteries of your production

Z-shaped conveyors are designed for lifting and lowering cargo from one height to another. The design consists of 3 sections: horizontal lower, inclined and horizontal upper, forming a single conveyor system in the shape of the Latin letter Z..

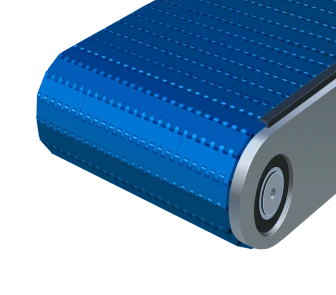

Z-shaped conveyors are mainly used to move small pieces of goods, as well as granular, small lumpy goods and containers of insignificant weight. Conveyor systems of this shape can be belt or modular belt based on the type of cargo and production conditions. To prevent products from falling and mixing, belts are additionally equipped with blades and separating dividers.

One Z-shaped conveyor replaces three, as it combines horizontal and inclined sections and saves working space due to the “broken” design.

Usually conveyors of this configuration are stationary, but they can be equipped with wheels to move around the workspace. It is also possible to equip with a reverse function. The angle of inclination of the middle section reaches 90°.

The speed of movement on all sections of the Z-shaped conveyor is the same, because the belt is driven by a single gearmotor.

We visit the enterprise, select a solution taking into account the customer's tasks, the characteristics of the transported product and the technological procss. We draw up a technical specification and prepare an estimate.

We are developing a technical solution, performing 3D modeling and engineering calculations. We are approving the project with the customer.

At the request of the client, we equip the conveyors with additional equipment and make adjustments. automated control of conveyor lines.

We carry out installation and commissioning, service, warranty and post-warranty service

We are training operators for subsequent pipeline maintenance