the arteries of your production

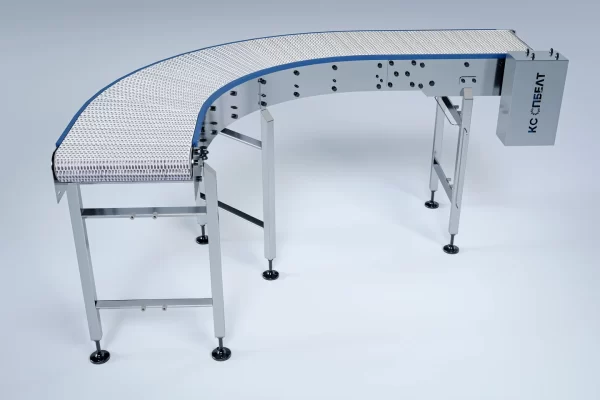

Modular conveyors are a type of conveyor belt type, where a modular belt made of high-strength plastic is used as a transportation route. In contrast to the belt conveyor, the modular conveyor is driven by means of sprockets.

Modular conveyor belt consists of individual plastic modules connected by metal pins or plastic locks. The length and shape of the belt can be easily changed, allowing the conveyor belt to be customized to meet the needs of a particular production.

Conveyors with modular belt are used for transportation of products between shops, in the areas of accumulation, sorting, packaging and redistribution of flows, as well as in the processes of freezing, washing and drying. It is most often found at food production facilities in meat, poultry and fish processing industry, bakery industry, production of semi-finished products, etc..

The conveyor system based on the modular belt can have straight, curved and lifting sections for use in conditions of limited space in the enterprise.

We produce modular belts from polypropylene (PP), polyacetal (POM), polyethylene (PE).

We visit the enterprise, select a solution taking into account the customer's tasks, the characteristics of the transported product and the technological process. We draw up a technical specification and prepare an estimate.

We are developing a technical solution, performing 3D modeling and engineering calculations. We are approving the project with the customer.

At the request of the client, we equip the conveyors with additional equipment and make adjustments. automated control of conveyor lines.

We carry out installation and commissioning, service, warranty and post-warranty service

We are training operators for subsequent pipeline maintenance