Task

In our practice we often encounter a situation when the Customer has neither drawings nor TOR, but only a video of the equipment, the analog of which should be manufactured, and the desired performance. This time the Customer needed to produce a conveyor for receiving and laying out on a metal grid slice of meat products after the slicing area.

Solution

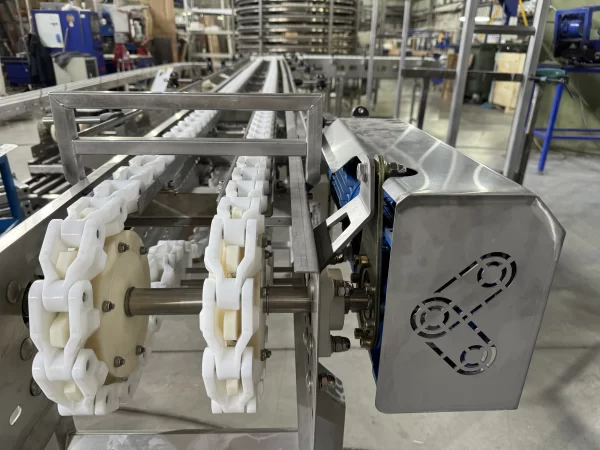

We designed and manufactured a structure of 4 conveyors:

- receiving belt conveyor;

- a reversible shuttle-type belt conveyor for evenly laying out the slices on the grid;

- belt conveyor for net feeding;

- roller conveyor for receiving nets with slides.

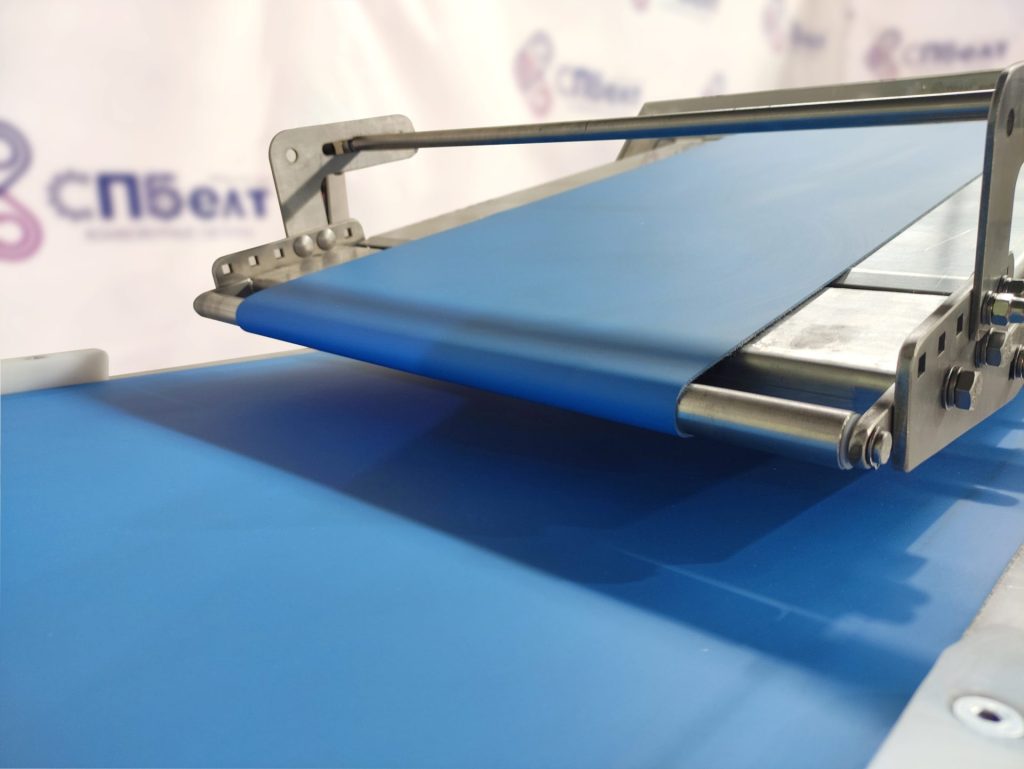

The belt conveyors are equipped with two-layer food-grade Amur Matt Blue polyurethane belt with matte smooth surface. The polyurethane has oil and grease resistant properties and the addition of graphite filament to the cord adds anti-static properties to the belt. Optical sensors and a pneumatic alignment system are used to monitor the precise positioning of the belt on the shafts.

The conveyor is equipped with polyethylene scrapers for cleaning the belt and trays for collecting product residue. Knife edge are made to transfer the slides between the two conveyors.

The plant is equipped with a sensor system to control the transfer of products from one stage to the other. As a result, the slices are placed on the grid evenly without voids and without overlapping products. The conveyor capacity is 5 nets per minute.

Result

A meat slice laying line was integrated into the production line at the Client's facility. The new equipment ensured minimization of manual labor and increased productivity in this area.

KS SPBelt specialists will always help to develop a solution and select components taking into account the equipment used in your production and the products being transported.