One of the leading companies in the bakery industry approached SPBelt with an order to design and manufacture a production line for cooling their products. Usually after baking, bread is cooled to the required temperature in a spiral cooler, then it goes to a slicing machine and then to a packaging machine. In the production of bakery and confectionery products, it is important to cool the products to ambient temperature in order to prevent condensation and preserve their consumer properties. Cooling must meet high hygiene standards and be done without manual labor, so production is automated.

Specialists of SPBelt have carried out a large-scale complex of works – from development of technical solution to commissioning of the technological line. During the development process we thoroughly studied all the peculiarities of the production process at the enterprise, analyzed the needs and requirements of the client to create the most efficient and reliable production line.

The solution included the following project phases:

- developing a technical solution;

- 3D modeling and engineering calculations;

- production of conveyor equipment;

- selection of refrigeration equipment;

- installation and commissioning of the technological line.

As a result, the SPBelt team has successfully designed and manufactured a product cooling line that fully meets the customer’s technical requirements. The result of our work was 58 units of equipment of various configurations and a spiral cooler for cooling. Now the company has a full cycle production line for cutting, cooling and packaging of bakery products. Let’s look at the rye-wheat bread cooling line in detail.

SYSTEM OF CONVEYERS OF THE COOLING LINE OF BREAD BREAD PRODUCTS

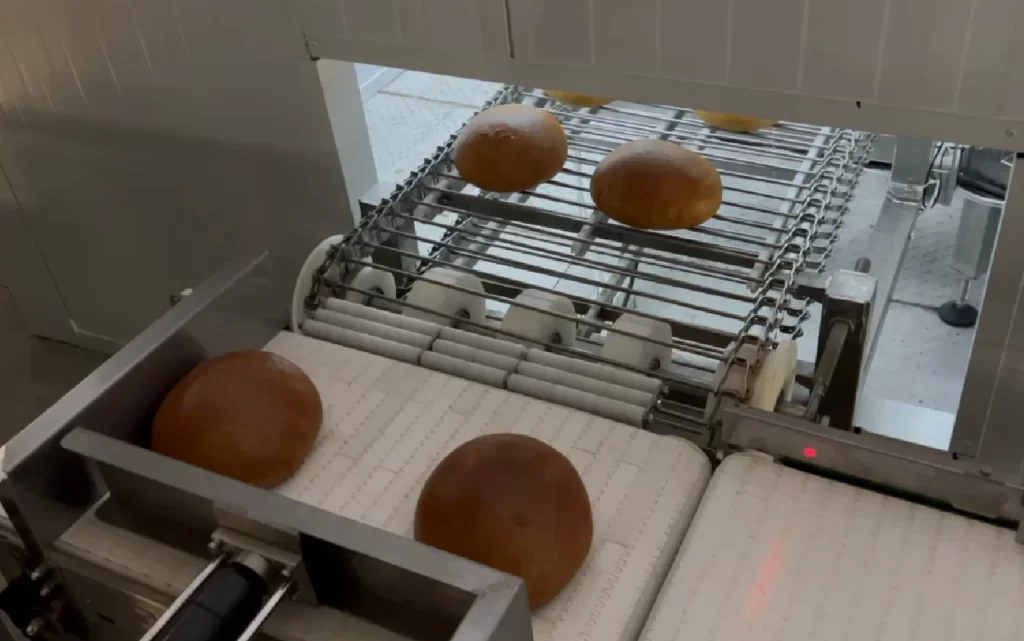

.The first step is to gently feed the bread from the baking oven grid onto the discharge conveyor by means of the “even row” device. The automatic, pneumatically actuated and sensor-controlled flap waits until all products have touched it, pauses for a short time and then opens. In this way, the entire row of bread is simultaneously sent to the diverting conveyor. It then enters the cooler for cooling.

To ensure that the bread is arranged in two rows on the spiral conveyor grid, a special transfer device, the “pusher”, is used. An alternative solution is the “helicopter” device.

The product cooling spiral cooler is the main stage of the whole production process of the bakery products cooling line. It can be divided into three parts – spiral conveyor, insulated chamber and refrigeration equipment.

The heart of the processing line is a side-driven spiral cooling conveyor (cooler). In the cooler the products are moved from one section of the production line to another at a certain speed. During the movement the bread cools down to the temperature required by the producer.

The insulated chamber is made of 80 mm thick sandwich panels with PIR filling. It is equipped with doors, lighting and a security system. Inside the chamber there is a Lu-ve dual-flow air cooler with Alupaint protective coating. The warm air intake from the bottom and the two-way discharge of cooled air ensures optimum air circulation in the chamber.

The refrigeration unit based on a semi-hermetic Bock reciprocating compressor is installed in the technical room. The Lu-ve air-cooled condenser is mounted on the roof of the production hall.

Bar spiral chutes are used to lower the bread from the top tier to the bottom tier and send it to the next conveyor.

Further on, using a system of different conveyors based on SPBelt’s ML modular belt, the product is fed to a bread slicer.

The arrow conveyor redirects the product flow to the bread slicer, directly to the packaging machine or to the rotating accumulation table. The accumulation table is used in the event that the packaging machine or bread slicer stops and the products accumulate.

Bridge conveyor is used to provide the possibility of passing from one zone to another through the conveyor line

.It should be noted that all conveyors are coordinated by a control system based on Siemens SIMATIC S-7-1200 controller. It allows the LCD panel to select modes of operation, visualizes all the necessary technological parameters, provides safe operation of the technological line as a whole.

4 Reasons to Choose a Lateral Drive SPIRAL CONVEYER

The spiral conveyor is the equipment that performs a key function in the bread cooling process. We specialize in the design and manufacture of spiral conveyors of various capacities and configurations. Let us emphasize all the advantages of the SPBelt spiral conveyor, which we offered to the customer as part of the process belt for cooling bakery products:

Side drive:

- Saving space inside the conveyor by eliminating the costly center drum:

- the possibility of building a spiral conveyor around the elements of building structures;

- the possibility of placing refrigeration equipment inside the spiral conveyor

- Less metal consumption due to side drive design.

- Easy to maintain and hygienic, as washing and cleaning of the equipment is easier.

Unique SPBelt solution

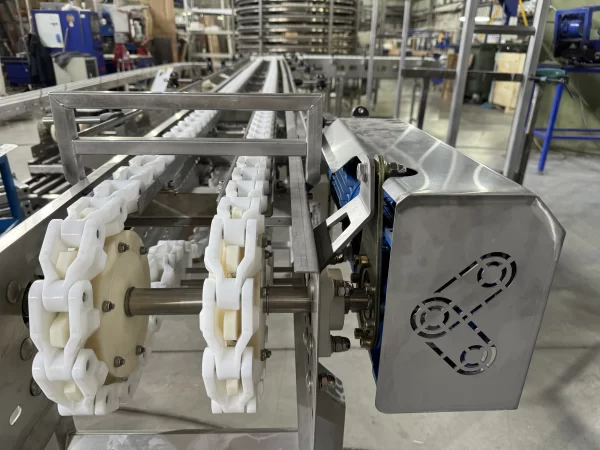

- In contrast to other conveyors with side drive spiral conveyor made by SPBelt does not require the use of lubricants in its operation, because we use a pair of friction stainless steel – polyethylene. The mesh moves on sliding profiles made of ultra-high molecular weight polyethylene, which ensures a constant low coefficient of friction between them.

- Prevents grease from getting on the product being transported.

- No additional costs for purchasing lubricants.

Proprietary mesh design:

- The mesh is single, stainless steel, and durable. It does not have any additional hold-down guides, inserts, hold-down guides, respectively no consumables.

- Works as smoothly and jerk-free as possible. The product maintains its position on the grid throughout the entire transportation time.

- No risk of mesh snagging as a result of excessive tension, which is often the case with the classic spiral system with a drive drum.

- The possibility of using different meshes in one spiral system.

Special drive sprocket design

- Easy installation due to the split design of the drive sprocket. The special tooth shape prevents the mesh from jumping between the teeth.

- The symmetrical shape of the sprocket teeth doubles its service life. If worn, the sprocket can be turned 180 degrees and continued to be used.

- The load capacity of the sprocket has been doubled with two rows of teeth.

Conveyor equipment plays an important role at all stages of bread production. Its use is especially relevant for the automation of production lines in enterprises with high productivity and relatively small product range. The realized project allowed our customer to significantly reduce costs, improve product quality and increase productivity. We appreciate our customer’s trust and strive to maintain the high level of our work.

Our company prides itself on its expertise in the manufacture of conveyor equipment and components, and is ready to offer customized solutions that meet the needs and requirements of any level of complexity. We value the trust of our customers and strive to maintain a high level of performance.