Task

The client needed to develop equipment for efficient defrosting of herring fish blocks and herring fillets. The task was to create a system that would ensure uniform defrosting of the product as a result of water and air circulation. Foreign suppliers who manufacture defrosters have either left our market or the cost of delivery has increased many times.

Solution

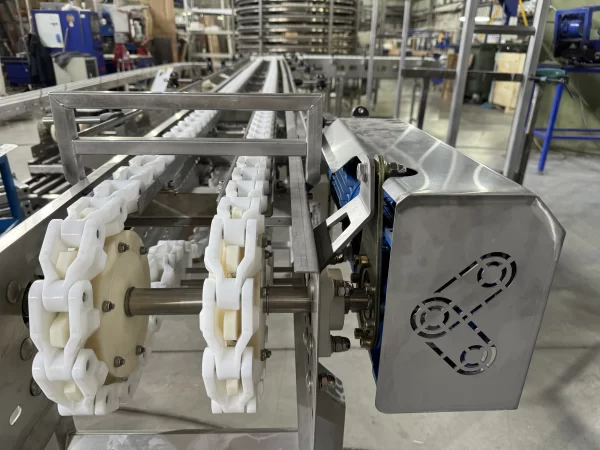

KS SPBelt designers have developed a water-type defroster with a bubbling function, which fully meets the customer's technical requirements. The equipment is a tub equipped with a lifting conveyor with a modular belt. This solution facilitates maintenance and the removal of residual products from the bottom of the bath.

The frame of the tub is made of stainless steel AISI 304 with additional stiffening ribs, resistant to deformation even when fully loaded.

Uniformity of defrosting and air supply to each point inside the defroster is ensured by strong and constant stirring (bubbling) of water. The air is pressurized into the defroster through the perforated bottom of the tub containing the frozen fish blocks. This technology ensures optimal defrosting due to the constant circulation of the product in the water.

At the optimal temperature of water in the bath from +15 ° C to +20 ° C defrosting time of 1 ton of frozen product is up to 1.5 hours.

Result

The supplied equipment allowed the client to significantly improve the efficiency of the fish defrosting process, reducing time costs.

The client emphasized the high quality of the end product - herring and herring fillets, and also noted that our equipment is not only comparable to imported defrosters, but also exceeds them in a number of parameters.