Task

Portioned pieces of dough were rolling down the inclined modular Z-shaped conveyor as they were moved upwards. A new solution for dough transportation had to be developed.

Solution

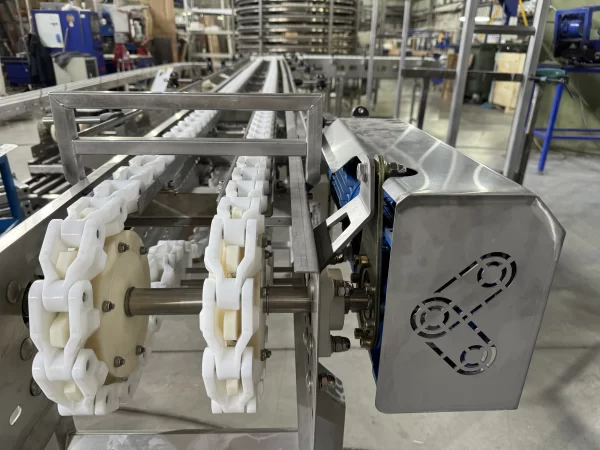

In our practice we have repeatedly faced such a problem of the customer. In this project, we designed and manufactured a construction of 3 belt conveyors for the specific site. The dough pieces from the dough making machine are conveyed to the horizontal receiving conveyor and then moved between two independent inclined conveyors to the next production area. The dough is held by the upper conveyor and therefore does not roll down. The gap adjustment is adjusted according to the size of the dough pieces.

Neva Matt belt is installed on the conveyors. The belt has a matt surface with increased abrasion resistance and tensile strength. On the drive surface of the belt there are longitudinal profiles for positioning the belt on the shaft. The conveyor is equipped with polyethylene scrapers for cleaning the belt from dough residues. At the customer's request, the conveyor frame is made of painted steel.

Result

The client is satisfied with the proposed solution, as he was able to solve his problem and reduce the number of detects in production. The construction of conveyors was optimally integrated into the production line.