Task

The customer needed to produce an analog of a foreign conveyor for dividing corrugated box cutting streams. It was necessary to provide for the possibility of changing the product entry point and a fixed exit point for centering the product on the production line.

Solution

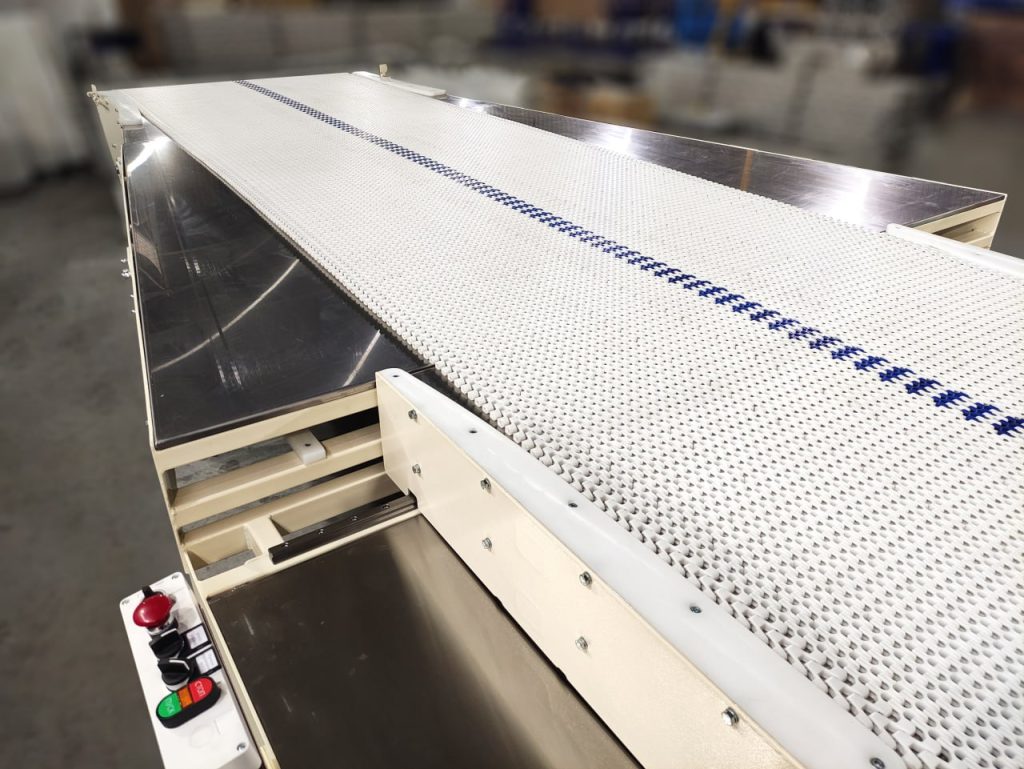

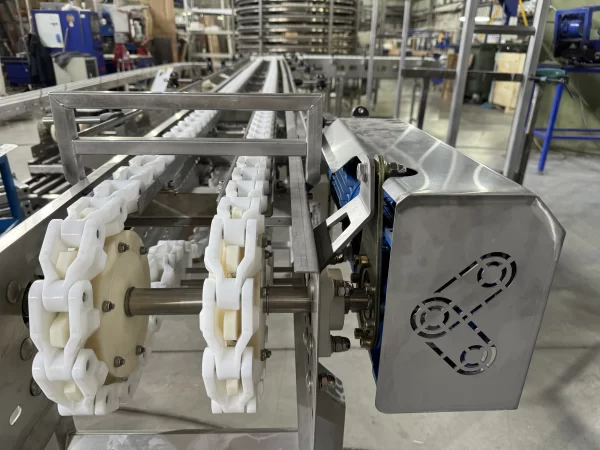

We designed according to the Customer's sketch and manufactured the divider. The conveyor table is made of stainless steel, which eliminates static electricity that can accumulate on the modular belt as a result of its friction against the working surface of the table.

The conveyor control system is integrated into the enterprise's automated process control system. The conveyor is equipped with a system of sensors that stop the line if the next section is still occupied by products. Belt speed on the conveyor is 45 m/min

The ML100R modular belt made of polyacetal is installed on the conveyor, as cardboard is a very abrasive product.

Result

The Divider from KS SPBelt is characterized by high quality of materials and assembly. The customer can be sure that at any time he will promptly receive spare modules and other components in case of need. Before shipment, the operation of the Divider was demonstrated to the customer at our production facility.